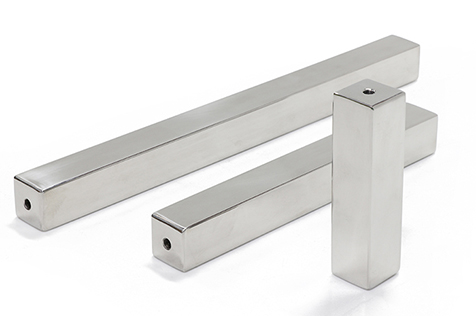

Bar magnets

How do you remove iron powder which has attached to the bar magnet?

It can be easily removed by patting over it using sticky tape.

Maintenance and replacement time

The stainless case is 0.5mm thick.

It may become thinner due to the hardness of the magnetic substance and contact friction.

Although the embedded magnets are permanent magnets, they have been embedded by applying resistance load.

Therefore, even if the magnets are used within the specification heat resistance temperature, they may demagnetize over time due to the repeated stress of fluctuating between hot and cold temperatures.

There is no definite timing for replacement, however we recommend regularly conducting surface magnetic flux density and appearance tests.

What is the recommended distance between each bar?

When laying out the bars, the distance between each bar is important.

Please adjust the processing speed suitable for your productivity according to the distance between the bars.

The distance is determined by what kind of magnetic substance you would like to process and at what speed.

- narrow

- wide

Introduced at the start of

- ron powder

(magnetic material) - Sorting object

(non-magnetic)

10 minutes later

- Narrow

- Wide

- Slow

- Processing speed

- Fast

How often is maintenance and replacement required?

The stainless case is 0.5mm thick.

It may become thinner due to the hardness of the magnetic substance and contact friction.

Although the embedded magnets are permanent magnets, they have been embedded by applying resistance load.

Therefore, even if the magnets are used within the specification heat resistance temperature, they may demagnetize over time due to the repeated stress of fluctuating between hot and cold temperatures.

There is no definite timing for replacement, however we recommend regularly conducting surface magnetic flux density and appearance tests.

- Narrow spaces

This will be a fine filter and the processing speed for separating magnetic substances will be slow.

- Wide spaces

-

This will be a rougher filter and the processing speed for separating magnetic substances will be faster.

- *In this case, the roughness of the filter and processing speed can be improved by making more than 2 layers of magnetic filters.

- *If there are multiple layers with narrow spaces in between the bars, although the processing speed will be slower, the attraction capacity will increase.

| Distance between bars | Recommended distance | Filter grain | Attraction capacity | Processing speed |

|---|---|---|---|---|

| Narrow | 40mm | Fine, thin | ○ | |

| Wide | 50mm | Rough, thick | ○ |

Discs / Rods

Discs / Rods Rings

Rings Arc Segment

Arc Segment Squares

Squares Spheres

Spheres Disc Countersunks

Disc Countersunks Square Countersunks

Square Countersunks A-Disc Countersunks

A-Disc Countersunks B-Disc Counterboreds

B-Disc Counterboreds C-Thread Male

C-Thread Male D-Thread Female

D-Thread Female E-Hooks

E-Hooks F-Eyelet hook

F-Eyelet hook G-Discs

G-Discs H-Filettatura Interno

H-Filettatura Interno LA-Square Countersunks

LA-Square Countersunks LB-Square Counterboreds

LB-Square Counterboreds LG-Squares

LG-Squares Bar

Bar Square

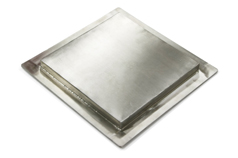

Square Rectangular Filter

Rectangular Filter Round Filter

Round Filter Plate

Plate Discs / Rods

Discs / Rods Squares

Squares Discs / Rods

Discs / Rods Rings

Rings Squares

Squares Rubber magnets

Rubber magnets Discs / Rods

Discs / Rods Squares

Squares