About the surface treatment of our neodymium magnets

For our neodymium magnets, we offer not only nickel plating but various kinds to suit your needs. In particular, our unique anti-rust coating technology "Hi-DEN Coat" substantially improves the anti-rust performance of neodymium magnets. Please consider our Hi-DEN Coat along with plated products.

Comparison of properties

| Material | Mark | Film thickness(μm) | orrosion resistance Salt water spray(Hr) |

Porosity | Demagnetization rate | Abstract colors | PCT (Hr) |

|---|---|---|---|---|---|---|---|

| "HDC coating epoxy MF304" |

MF304 Epoxy |

5-100 | >500 | - | - | Multi-colors | >100 |

| "HDC coating polyimide MF305" |

MF305 Polyimide |

5-50 | >400 | - | - | Multi-colors | >100 |

| Zinc | Zn | 10-15 | >24 | <0.1 | <0.2% | White | >16 |

| Coloured zinc | Colour-Zn | 10-15 | 72 | <0.1 | <0.1% | Multi-colors | >24 |

| Nickel | Ni | 10-20 | 4 | <0.5 | <0.3% | Silver | >16 |

| Double nickel | Double-Ni | 15-20 | 24 | <0.2 | <0.3% | Silver | >16 |

| Nickel-copper-nickel | Ni-Cu-Ni | 15-30 | >48 | <0.1 | <0.1% | Silver | >42 |

| Zinc-nickel-alloy | Zn-Ni Alloy | 10-20 | >720 | <0.1 | <0.1% | Multi-colors | >72 |

| Other company's Epoxy | EPOXY | 10-50 | >300 | - | - | Black | >24 |

| Electroless Nickel | Electroless Ni | <1 | >72 | - | - | Silver | >24 |

Salt spray test:37-39℃ 5%NaCl PH6.5-7.0 1.5ml/Hr

PCT: 120℃, 2atm, 100%RH, 12Hr.

Appearance and characteristics

φ10mm×10mm |

Element symbol |

Name of element |

Properties |

Usage |

|---|---|---|---|---|

|

3CrZn | Trivalent chromium zinc | Chromate treatment. Recently hexavalent chromium has been regulated as an environmentally destructive substance and replaced with trivalent chromium | Eletronic parts industrial tool parts |

|

Ag | Sliver | Silver has the best electric conductivity out of all the metals, low contact resistance and good solderability but is easy to discolor. | Eletronic parts Connectors Eating utensils Accessories |

|

Au | Gold | Gold has good corrosion and oxidation resistance along with low electrical resistance. | Eletronic parts Electrical contact parts Decorations Accessories |

|

Cr | Chrome | Chrome has good abrasion and oxidation resistance and will not lose its shine in the atmosphere. | Exterior parts Medical supplies Audio-visual equipment Accessories |

|

Cu | Copper | Copper is easy to discolor so is used as a base. It is used to fill in dents and bring out a shine. | Casting products ABS resin base |

|

CuZn | Brass | Brass materials change color easily and are usually used as foundation. Brass materials are often used in ancient ornaments. | Ancient color ornaments |

|

Ni | Nickel | Nickel is chemically stable and has good anti-rust properties. It can be used for a wide range of purposes and is used as a base for gold plating, chrome plating etc. It can cause skin irritation. |

Eletronic parts Connectors Base platings Accessories |

|

NiBlack | Black nickel | Black nickel is an alloy plating made of nickel, zinc and sulphur. The color may vary depending on the type of plating used as a base. | Decorations Accessories |

|

Sn | Tin | Tin has excellent anti-corrosion properties and does not oxidize easily. It does not lose its shine easily and is safe to use in foods. | Eating utensils Cans Tin objects Decorations Accessories |

|

Rh | Rhodium | Rhodium has excellent anti-corrosion properties and does not oxidize easily. It does not lose its shine easily and is safe to use in foods. | Eletronic parts Electrical contact parts Audio parts Decorations Accessories |

|

- | Un-treated | No surface treatment coating. Rust will develop easily on neodymium magnets. | |

|

- | Nylon | Made with no organic solvent and used in food processors and medical devices. Passed the Food Sanitation Act. | Toys Small articles |

|

- | Polyimide MF305 | High impact strength, resists bends, and can be used in high temperature. | Eletronic parts Small articles For bending after painting |

| - | - | Epoxy MF304 | High solidity of resin / Flame retardance regulation: UL94 / V-0 Certified | Eletronic parts Small articles |

| - | - | Epoxy MF303 | High solidity of resin / Easy to polish | Decorations |

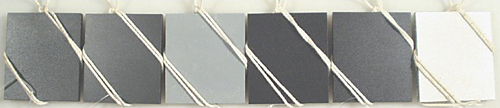

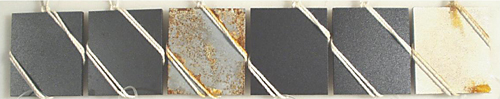

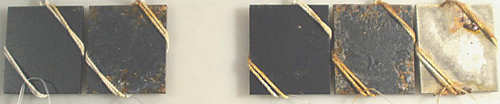

Anti-rust performance test Ni/Zu/Epoxy

| Magfine | Company[S] | Other companies |

Magfine | Company[T] | Magfine | |

|---|---|---|---|---|---|---|

| Duration | HDCcoating epoxy MF304 |

Normal epoxy |

Anti-rust undercoat Zn for automobiles Zn |

HDC coating polyimide MF305 |

Normal epoxy |

NiCuNi |

| Before start of test |  |

|||||

| After 72 hrs |  |

|||||

| After 312 hrs |  |

|||||

| After 504 hrs |  |

|||||

Salt spray test:37-39℃ 5%NaCl PH6.5-7.0 1.5ml/Hr

PCT: 120℃, 2atm, 100%RH, 12Hr.

For details of Hi-DEN Coat click here

Discs / Rods

Discs / Rods Rings

Rings Arc Segment

Arc Segment Squares

Squares Spheres

Spheres Disc Countersunks

Disc Countersunks Square Countersunks

Square Countersunks A-Disc Countersunks

A-Disc Countersunks B-Disc Counterboreds

B-Disc Counterboreds C-Thread Male

C-Thread Male D-Thread Female

D-Thread Female E-Hooks

E-Hooks F-Eyelet hook

F-Eyelet hook G-Discs

G-Discs H-Filettatura Interno

H-Filettatura Interno LA-Square Countersunks

LA-Square Countersunks LB-Square Counterboreds

LB-Square Counterboreds LG-Squares

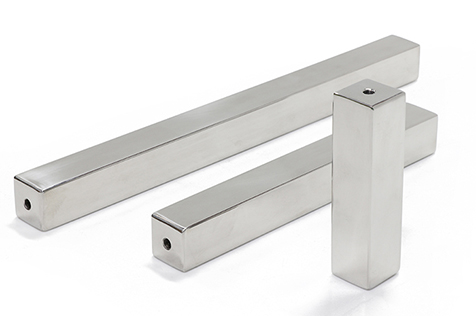

LG-Squares Bar

Bar Square

Square Rectangular Filter

Rectangular Filter Round Filter

Round Filter Plate

Plate Discs / Rods

Discs / Rods Squares

Squares Discs / Rods

Discs / Rods Rings

Rings Squares

Squares Rubber magnets

Rubber magnets Discs / Rods

Discs / Rods Squares

Squares