Specified magnetic characteristics

The magnetic characteristics of materials have different standardized capacities on each grade. Those are values of matrix samples (Ratio: Height / Diameter = 0.7) calculated by a BH analyzer before cutting. The magnetic characteristics of finalized magnets after cutting depend on the shape ratio, temperature, and environment. Therefore, they differ from the magnetic characteristics of materials written below. Values and information currently available may change without notice due to improvements and other factors.

| Material | Grade |

Br | Hcb | Hcj | (BH)max | TC | TW | αBr %/℃ |

αHcj Hcj/℃ |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sm:Co |

Unit | mT | KGS | KA/m | KOe | KA/m | KOe | KJ/m3 | MGoe | ℃ | ℃(H/D=0.7) | %℃ | %℃ |

| 1:5 | YX10 | 590-630 | 5.9-6.3 | 460-493 | 5.8-6.2 | 1430-1830 | 18-23 | 68-80 | 8.5-10 | 700 | 250 | - | - |

| YX12 | 700-740 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | - | - | |

| YX16 | 810-850 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 | |

| YX18 | 850-900 | 8.5-9.0 | 660-700 | 8.3-8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX20 | 900-940 | 9.0-9.4 | 680-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX22 | 920-960 | 9.2-9.6 | 710-750 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX24 | 960-1000 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| YX18s | 850-900 | 8.5-9.0 | 660-700 | 8.3-8.8 | 1433-2000 | 18-25 | 135-151 | 17-19 | 750 | 250 | -0.045 | -0.28 | |

| YX20s | 900-940 | 9.0-9.4 | 680-725 | 8.5-9.1 | 1433-2000 | 18-25 | 143-160 | 18-20 | 750 | 250 | -0.045 | -0.28 | |

| YX22s | 920-960 | 9.2-9.6 | 710-750 | 8.9-9.4 | 1433-2000 | 18-25 | 160-175 | 20-22 | 750 | 250 | -0.045 | -0.28 | |

| 2:17 | YXG24H | 950-1020 | 9.5-10.2 | 700-750 | 8.7-9.4 | ≥1990 | ≥25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG26H | 1020-1050 | 10.2-10.5 | 750-780 | 9.4-9.8 | ≥1990 | ≥25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG28H | 1030-1080 | 10.3-10.8 | 756-796 | 9.5-10.0 | ≥1990 | ≥25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG30H | 1080-1100 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG22 | 930-970 | 9.3-9.7 | 676-740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG24 | 950-1020 | 9.5-10.2 | 700-750 | 8.7-9.4 | ≥1433 | ≥18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG26 | 1020-1050 | 10.2-10.5 | 750-780 | 9.4-9.8 | ≥1433 | ≥18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG28 | 1030-1080 | 10.3-10.8 | 756-796 | 9.5-10.0 | ≥1433 | ≥18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG30 | 1080-1100 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG32 | 1100-1130 | 11.0-11.3 | 811-845 | 10.2-10.6 | ≥1194 | ≥15 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG26M | 1020-1050 | 10.2-10.5 | 716-780 | 9.0-9.8 | 955-1273 | 12-16 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG28M | 1030-1080 | 10.3-10.8 | 716-796 | 9.0-10.0 | 955-1273 | 12-16 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG30M | 1080-1100 | 10.8-11.0 | 716-835 | 9.0-10.5 | 955-1273 | 12-16 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG32M | 1100-1130 | 11.0-11.3 | 716-845 | 9.0-10.6 | 955-1273 | 12-16 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG24L | 950-1020 | 9.5-10.2 | 557-716 | 7.0-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG26L | 1020-1050 | 10.2-10.5 | 557-748 | 7.0-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG28L | 1030-1080 | 10.3-10.8 | 557-765 | 7.0-9.9 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG30L | 1080-1150 | 10.8-11.5 | 557-795 | 7.0-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG32L | 1100-1150 | 11.0-11.5 | 557-810 | 7.0-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

Discs / Rods

Discs / Rods Rings

Rings Arc Segment

Arc Segment Squares

Squares Spheres

Spheres Disc Countersunks

Disc Countersunks Square Countersunks

Square Countersunks A-Disc Countersunks

A-Disc Countersunks B-Disc Counterboreds

B-Disc Counterboreds C-Thread Male

C-Thread Male D-Thread Female

D-Thread Female E-Hooks

E-Hooks F-Eyelet hook

F-Eyelet hook G-Discs

G-Discs H-Filettatura Interno

H-Filettatura Interno LA-Square Countersunks

LA-Square Countersunks LB-Square Counterboreds

LB-Square Counterboreds LG-Squares

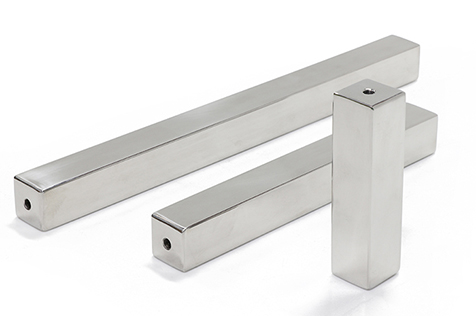

LG-Squares Bar

Bar Square

Square Rectangular Filter

Rectangular Filter Round Filter

Round Filter Plate

Plate Discs / Rods

Discs / Rods Squares

Squares Discs / Rods

Discs / Rods Rings

Rings Squares

Squares Rubber magnets

Rubber magnets Discs / Rods

Discs / Rods Squares

Squares